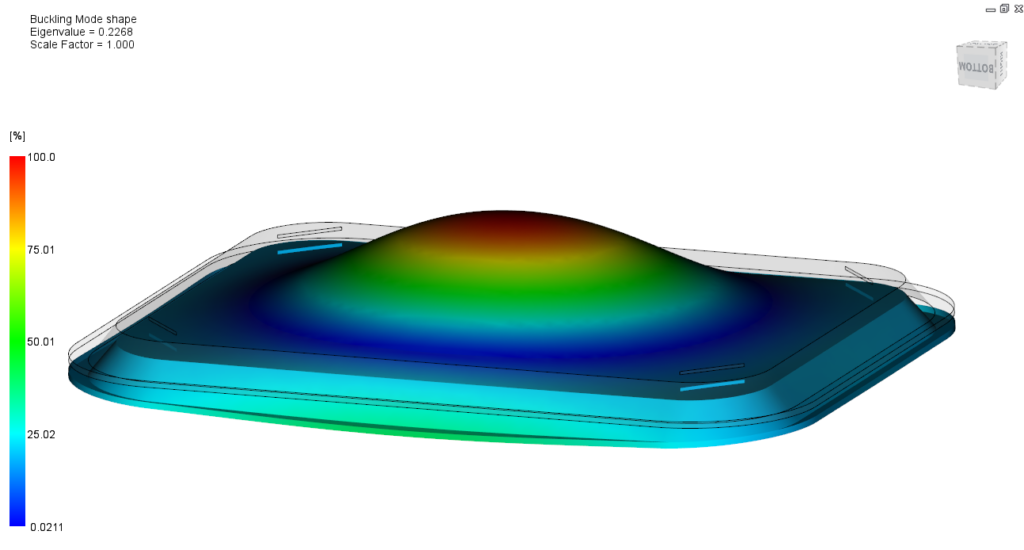

Run a Buckling Analysis

Most of the deflection observed in plastic part warpage would be considered stable, or linearly proportional to the applied shrinkage stress. Sometimes with low modulus materials and weak part structures, we may see unstable loading or buckling.

Buckling is available in both Midplane and 3D meshes. If we have a true 3D part/mesh that is thick and chunky, usually this type of geometry will be stable in loading and will not buckle. Larger, flat parts that have low modulus materials are where I think long and hard about running a Buckling analysis. These parts should be easy to mesh in Midplane.

If you are in Midplane – just run an Automatic Warp analysis. This will run Buckling analysis and determine if the part buckles (then runs a large deflection) or is stable (then runs a small deflection). Looking at Log files, we can find the Eigenvalues. If the lowest positive Eigenvalue is less than 1, the part will buckle.

Since the loading is unstable, we can’t use traditional means to determine the cause of warp. With Buckling, we head back to the log files to look at the Sensitivity Factors. The variant with the highest absolute value is the cause of our warp.

Have you ever run a buckling analysis in Moldflow Insight?